Yeah, it seemed like a lot to me as well. They did make the dimple ring as well, but come on guys! Unfortunately my favourite (cheap) machine shop closed down last year, this was my first and probably last visit to these guys. I have to scout around and find out what other machine shops are in town.

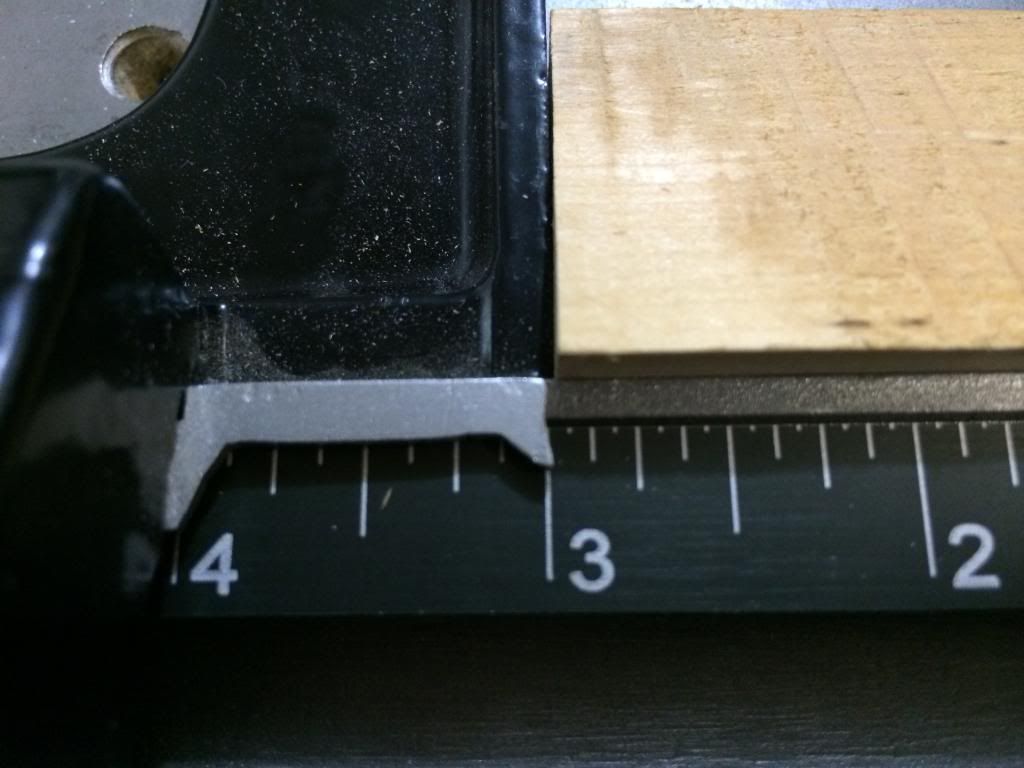

I was able to find my spare nut (actually I found two), I definitely had to widen my search area. It was in a plastic bag hanging from a nail in the garage. Not sure how it got thee, but I'm happy I found it. You can see it is not exactly the same as the original on my machine ( new one is on the right, maybe it's from a 100?). I tested it on my machine though and it fit and worked without issue.

I decided to try to JB Weld new threads on it. There was little to lose, since I had my original still, and one further spare nut. So the first step was to grind off the old threads. I used a piece of the Acme rod with some coarse sandpaper on it to grind them off.

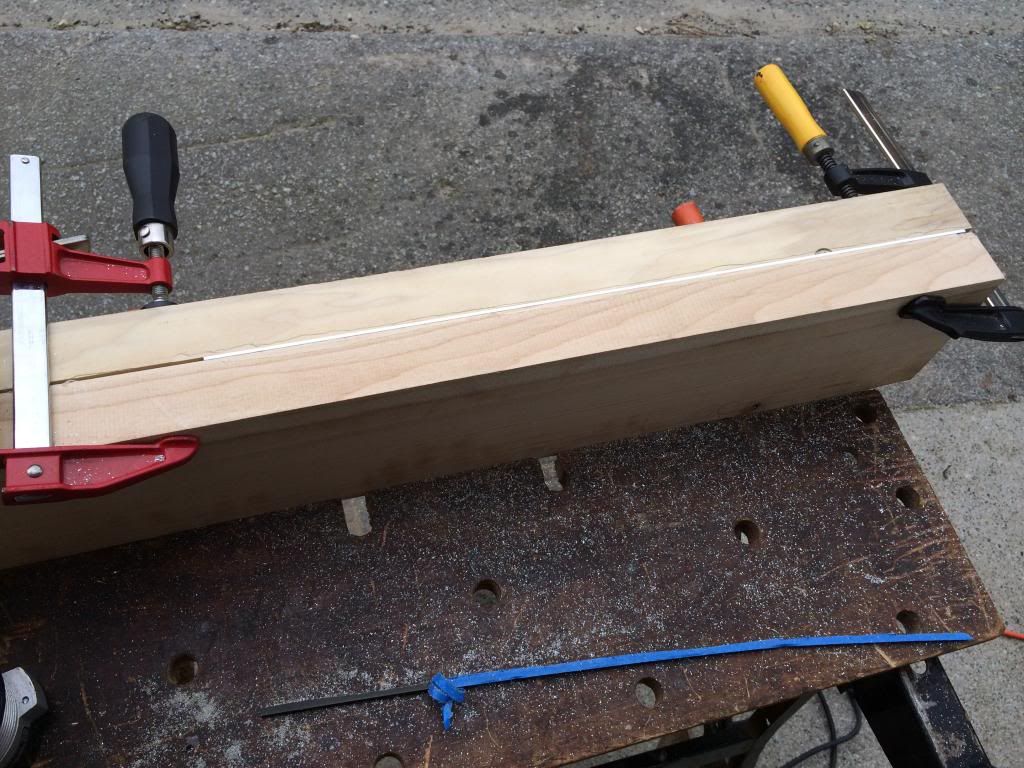

That worked pretty well. I then hit the Acme rod I was going to use as a mold with some wax, then applied the JB Weld, and clamped it overnight.

It seems that the wax was not an effective release agent, as most of the JB Weld remained adhered to the rod rather than the nut! So I tried it again, but with WD40 as the release agent, and got the same result. So now I am a little bit stalled again, but will report back when I figure it out.

As for the faceplate, mine is quite shiny, makes me think it has been chrome plated or something? I will take it into a machine shop and see what they say.