New Tools

Moderator: crzypete

-

mystry_tour

- Posts: 357

- Joined: Mon Mar 13, 2006 9:33 pm

- Location: Greenville Tenn

New Tools

Picked up a new old BP mill and heavy ten today. The BP is nice, one shot oiler dial speed control real nice powerfeed with rapid. The SB is is a pedistal type with a turrent tail stock. I will get some pic when they get delivered

Reg

Reg

I fought to keep the Gov. in power......they keep screwing around I'll fight to get rid of them.

-

mystry_tour

- Posts: 357

- Joined: Mon Mar 13, 2006 9:33 pm

- Location: Greenville Tenn

I do Nic. The mill is a newer one with much better aminities. It has the speed control that you can crank to change the spindel speed, a one shot oiler and larger table. The power feed is about a $600 powerfeed which mine is the original mechanical type . Mine I have to stop the machine and then I have to change the belts on the pully.The lathe was such a good deal I couldn't pass. It was a if you take both I will give you a good price. So I had the cash to spare.....and well you know the rest. I will put the lathe into a rebuild mode shortly after I put the DRO on the mill. I bought the DRO last year just never got around to puting it on. I will put it on the new mill before I hook it up.

Reg

Reg

I fought to keep the Gov. in power......they keep screwing around I'll fight to get rid of them.

Hey Tour, Very cool additions, where are our pics?

My first lathe was a heavy ten and it is remarkable what can be accomplished with them. If I am not mistaken, this gives you two?

The bridgeport sounds like a nice machine as well. DOes it have chrome ways- sure sounds like it should with the other amenities? The varied speed pulleys are great, but they have a tendency to wear out bushings and make a knocking noise. I think in a non-production environment it is less of an issue, if they are good, they will probably stay good, and if they go bad, it should be a one time fix.

Lastly, you will absolutely love the DRO. I have almost forgotten how to read dials

Pete

My first lathe was a heavy ten and it is remarkable what can be accomplished with them. If I am not mistaken, this gives you two?

The bridgeport sounds like a nice machine as well. DOes it have chrome ways- sure sounds like it should with the other amenities? The varied speed pulleys are great, but they have a tendency to wear out bushings and make a knocking noise. I think in a non-production environment it is less of an issue, if they are good, they will probably stay good, and if they go bad, it should be a one time fix.

Lastly, you will absolutely love the DRO. I have almost forgotten how to read dials

Pete

-

mystry_tour

- Posts: 357

- Joined: Mon Mar 13, 2006 9:33 pm

- Location: Greenville Tenn

Hey Pete. I was suppose to get it today but it came the rain from hell. Hopefully I will have it tomorrow or when we get a break in the weather. I will be sure to get pics.

Yes that will be two 10's. I will be rebuilding one to rebuild the other to sell one I understand the DRO thing. I am relearing the art of remembering.....ummmmm was that a hundred thousands or 200.

I understand the DRO thing. I am relearing the art of remembering.....ummmmm was that a hundred thousands or 200.

I have had it for a year. I will hook it up befor I put power to it so I won't tarry on that item again

Reg

Yes that will be two 10's. I will be rebuilding one to rebuild the other to sell one

I have had it for a year. I will hook it up befor I put power to it so I won't tarry on that item again

Reg

I fought to keep the Gov. in power......they keep screwing around I'll fight to get rid of them.

-

mystry_tour

- Posts: 357

- Joined: Mon Mar 13, 2006 9:33 pm

- Location: Greenville Tenn

Got the mill and lathe last night but the camra was dead. I will get battries today and post the pics. It is a mess and needs painting bad. Everything seems to work well and I will be attaching the dro after I get it cleaned up a bit

Reg

Reg

I fought to keep the Gov. in power......they keep screwing around I'll fight to get rid of them.

-

mystry_tour

- Posts: 357

- Joined: Mon Mar 13, 2006 9:33 pm

- Location: Greenville Tenn

Well heres a few pic I snaged today. I did a bit of cleaning to have a better look. I don't think the ways are chrome Pete but its still in better shape that my older round ram

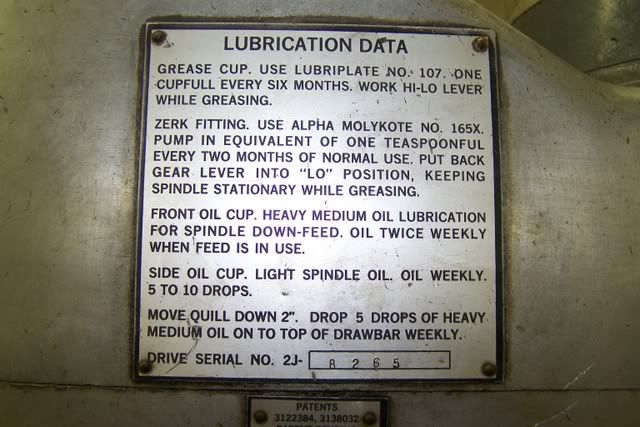

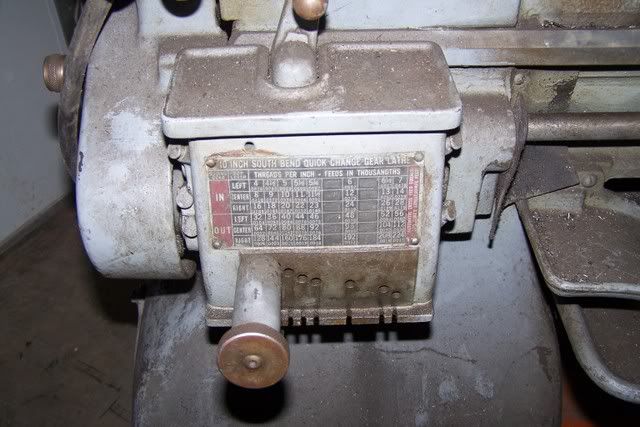

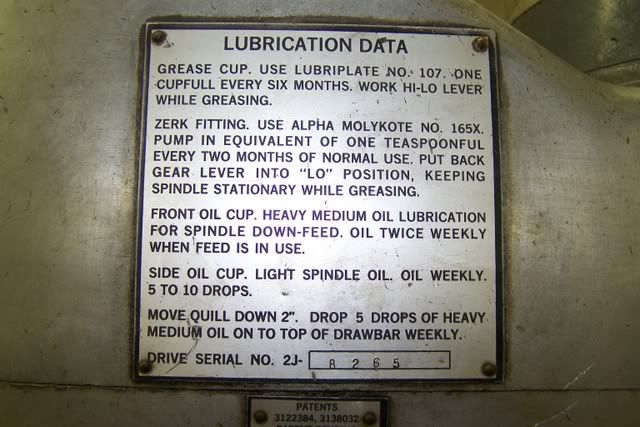

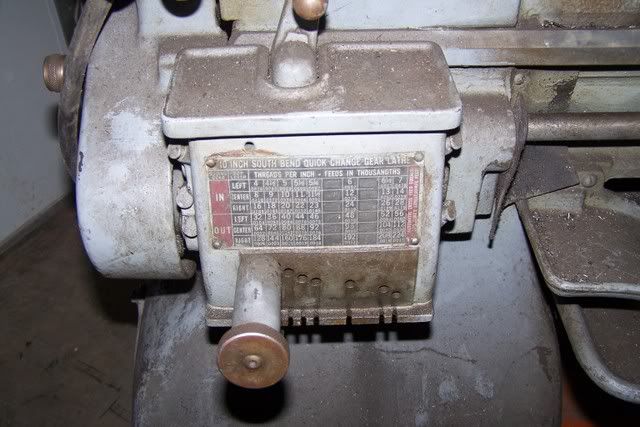

....And heres the lathe

hope I didn't ben the rules makeing too many pick in one post. Not really sure what they are

Reg

....And heres the lathe

hope I didn't ben the rules makeing too many pick in one post. Not really sure what they are

Reg

I fought to keep the Gov. in power......they keep screwing around I'll fight to get rid of them.

Nice score!

That turret on the southbend could be useful. Ant the j head seems to be in good shape. How big is the table? I have the same power feed and I am sure that you will love it. I have the same oiler but I could not get it to work. I did not put much time into it so I look forward to learning from your efforts.

Congrats

Nektai

That turret on the southbend could be useful. Ant the j head seems to be in good shape. How big is the table? I have the same power feed and I am sure that you will love it. I have the same oiler but I could not get it to work. I did not put much time into it so I look forward to learning from your efforts.

Congrats

Nektai

-

mystry_tour

- Posts: 357

- Joined: Mon Mar 13, 2006 9:33 pm

- Location: Greenville Tenn

I was cleaning and tramming today. The pin, or setscrew in the collet holder is broken so I will try to replace that tomorrow. I have to fix the brake since it doesn't work. The oiler dose work sothat is a good thing. Yes Nek the powerfeed is great I got to use it when I was looking at it.

You migh be intrested in this if you don't already have it

http://www.kneemills.com/index.asp?html=Documentation

LOTS of info even on your oiler.

Yes thatturent came originally on the lathe. That is the reason the ways are in great shape. I plan on putting a tail stock on it. I went looking on Ebay and mannnnnn talk about sticker shock. I posted it in a fourm and a guy out in Cal had one that the locking handle was brok and the pain was sad but it worked and the casting is good so he sent it to me for shipping.....

talk about sticker shock. I posted it in a fourm and a guy out in Cal had one that the locking handle was brok and the pain was sad but it worked and the casting is good so he sent it to me for shipping.....  . I'll let you know how the oiler pans out as i am thinking about haveing the table reground.....Oh it is a 42" table

. I'll let you know how the oiler pans out as i am thinking about haveing the table reground.....Oh it is a 42" table

Reg

You migh be intrested in this if you don't already have it

http://www.kneemills.com/index.asp?html=Documentation

LOTS of info even on your oiler.

Yes thatturent came originally on the lathe. That is the reason the ways are in great shape. I plan on putting a tail stock on it. I went looking on Ebay and mannnnnn

Reg

I fought to keep the Gov. in power......they keep screwing around I'll fight to get rid of them.

Hey Tour, We are into pictures, I am not sure you can post too many- I am not even sure if the software has a limit per post.

Thanks so much for sharing. nice additions to the shop.

With the turret remember that you can always put a center in one of the stations and use it as a tailstock- makes drilling with the other stations a breeze. This is especially handy because I find my lathe work is more than 50% drilling with the tailstock.

I don't know how much research you have done into replacing the pin, but I have done a little and can give you 2 cents of advice on it.

1- it is actually not needed, but I like having it myself.

2- you need to drop the bearing cap on the spindle to access it, it is important to mark the position before you drop it- it does not get fully tightened- score a line across to indicate where to tighten too.

3- The pin is a specialized setscrew- I think you can buy them from MSC in their bridgeport parts section for like $5

4- I think it is a fairly easy job, but have never tried it.

Pete

Thanks so much for sharing. nice additions to the shop.

With the turret remember that you can always put a center in one of the stations and use it as a tailstock- makes drilling with the other stations a breeze. This is especially handy because I find my lathe work is more than 50% drilling with the tailstock.

I don't know how much research you have done into replacing the pin, but I have done a little and can give you 2 cents of advice on it.

1- it is actually not needed, but I like having it myself.

2- you need to drop the bearing cap on the spindle to access it, it is important to mark the position before you drop it- it does not get fully tightened- score a line across to indicate where to tighten too.

3- The pin is a specialized setscrew- I think you can buy them from MSC in their bridgeport parts section for like $5

4- I think it is a fairly easy job, but have never tried it.

Pete

-

mystry_tour

- Posts: 357

- Joined: Mon Mar 13, 2006 9:33 pm

- Location: Greenville Tenn

Thanks Pete. Yes I did a little reasurch. You are correct in the takeing it apart and marking the nose piece. If by chance someone doesn't mark it the distance between the cap and the spinel sholder is .003. but its good to mark. The screw is a 1/4X32X3/8 half dog. I will try to make it in the lathe, or at least the half dog first. Too there is a lock set screw on top of that to keep it in place.

Now I will be looking to find the problem with the brake tomorrow....

Think I might paint that thing Black and Gold like the PM....what ya think

Reg

Now I will be looking to find the problem with the brake tomorrow....

Think I might paint that thing Black and Gold like the PM....what ya think

Reg

I fought to keep the Gov. in power......they keep screwing around I'll fight to get rid of them.

-

mystry_tour

- Posts: 357

- Joined: Mon Mar 13, 2006 9:33 pm

- Location: Greenville Tenn

-

mystry_tour

- Posts: 357

- Joined: Mon Mar 13, 2006 9:33 pm

- Location: Greenville Tenn

I talked to a guy this morning Pete from Industral Control about some parts. Wonderful guy. He had all the answers I needed and actually works on the BP mills. Their website is great, actually shows pics of the parts in the head. He emailed me great "drawing" of assembly. Good source for you and others.

Heres their site http://www.icai-online.com/home.php?cat=263

Reg

Heres their site http://www.icai-online.com/home.php?cat=263

Reg

I fought to keep the Gov. in power......they keep screwing around I'll fight to get rid of them.

-

mystry_tour

- Posts: 357

- Joined: Mon Mar 13, 2006 9:33 pm

- Location: Greenville Tenn

Well heres the up date on the mill. I changed the bearing in the upper part of the head. It worked out great. It is almost silent. I do think the high speet gears are a bit worn and the partss are around $600. I can live sith it. I have a bit of it painted but it turned cold so I am waiting to finish up.....maybe Wed. suppose to be 58..

Also I got the lathe scattered all over the shop now and have a lot of it striped and ready to paint. The lathe is pretty nasty so it will take a bit of elbo work to get it clean.

Reg

Also I got the lathe scattered all over the shop now and have a lot of it striped and ready to paint. The lathe is pretty nasty so it will take a bit of elbo work to get it clean.

Reg

I fought to keep the Gov. in power......they keep screwing around I'll fight to get rid of them.