So the Glider I picked up must have come straight from a print shop (via ~30 years in dusty storage). It has quite a thick coating of dust on it, as well as visible lead chips/flakes. Presumably some portion of the dust is lead dust too.

Once I get it cleaned up in the garage I'd like to bring it into my basement shop, so I really want ALL the lead off of it. I want to avoid contaminating the garage or the basement shop with lead.

My plan is as follows:

First rent a HEPA vac and vacuum off as much of the loose stuff as I can.

Second, disassemble the entire saw wiping it down with a cleaner like TSP as I go.

Third, take the parts to be sand/walnut/glass bead blasted. (Some parts may not be suitable to be blasted so I would have to clean some other way)

Fourth, repaint, reassemble, tune up and enjoy!

One unresolved problem is the motor. I imagine great clouds of lead dust flying out when I turn it on for the first time. It'll need to be disassembled and cleaned before I fire it up. It might be tough to get all the dust out of the motor as it cannot be blasted clean and it will likely have a ton of hard to get at places full of dust.

So I am hoping that others might have some suggestions on what to do, other than "Don't worry about it a little lead dust won't hurt you!"

Dan

Cleaning a Hammond Glider

Moderator: crzypete

Hi Dan,

I might not use the vac. I am not sure what a Hepa filter would do but I have heard horror stories about the exhaust distributing the hazardous material everywhere. Perhaps paper towel moistened with paint thinner or denatured alcohol to remove and dispose of that layer of lead. That is probably what I would do.

I might not use the vac. I am not sure what a Hepa filter would do but I have heard horror stories about the exhaust distributing the hazardous material everywhere. Perhaps paper towel moistened with paint thinner or denatured alcohol to remove and dispose of that layer of lead. That is probably what I would do.

Nektai,

Thanks for the reply. I am unsure about whether the vacuum is a good idea or not.

Several government websites suggest using a HEPA vac for lead, others recommend just rinsing with a rag damped with TSP or warm water. Granted, these sites are for homeowners with lead paint issues.

I am starting to think that just wiping it down may result in less dust getting tossed around in the air as you suggest, although the HEPA filters are pretty good. I think they capture everything down to 1 micron.

I'm not planning on starting for a few weeks (a couple other resto projects in front of it!), so I welcome any other suggestions.

Dan

Thanks for the reply. I am unsure about whether the vacuum is a good idea or not.

Several government websites suggest using a HEPA vac for lead, others recommend just rinsing with a rag damped with TSP or warm water. Granted, these sites are for homeowners with lead paint issues.

I am starting to think that just wiping it down may result in less dust getting tossed around in the air as you suggest, although the HEPA filters are pretty good. I think they capture everything down to 1 micron.

I'm not planning on starting for a few weeks (a couple other resto projects in front of it!), so I welcome any other suggestions.

Dan

OK so I started on the disassembly. I decided to just take it apart carefully, using latex gloves, old shoes, and a protective disposable coveralls. There is some dust spilling onto the floor which I will clean up afterwards. Also, the tools are getting all dirty and contaminated so I will probably just throw them out.

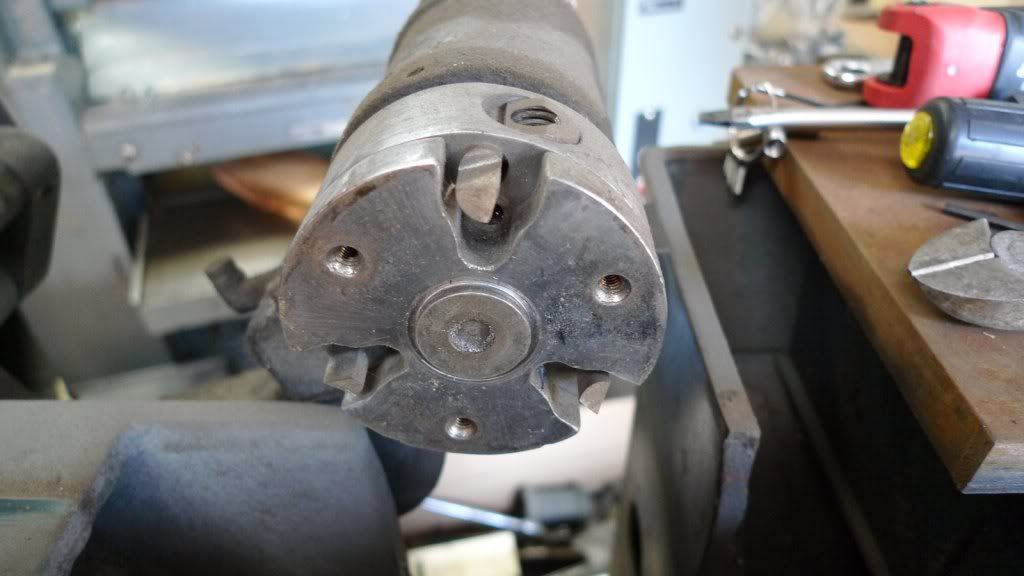

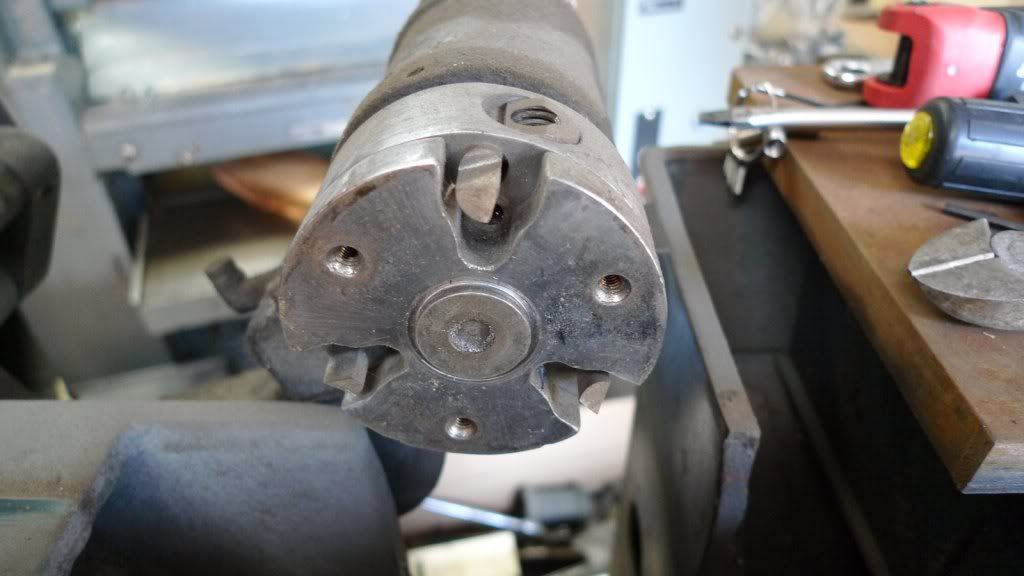

A few pictures. What may appear to be filings is lead chips. Many of the Allen screws' heads are so packed with it that the key will not fit into them without first cleaning out!

I sure hope it is worth all this!

A few pictures. What may appear to be filings is lead chips. Many of the Allen screws' heads are so packed with it that the key will not fit into them without first cleaning out!

I sure hope it is worth all this!