Good news: This mill does vertical and horizontal and any angle in between. It is smaller than a Bridgeport but more rigid. The mill is in good working condition. I recently scrubbed out the gearbox with mineral spirits and refilled it with fresh oil. I repacked the bearing with high quality synthetic grease. All the travel on the ways feels smooth and tight. The motor is the original 1.5 HP 3 phase GE made in Schenectady. I cleaned out the motor and repacked the ball bearings with synthetic grease. It runs great, super smooth. The mill comes with a brand new 10 piece set of collets that I bought off ebay for $175 plus shipping. I have not even used the collets. The collets are included. See the sellers website for info on the collets http://www.tools4cheap.net/proddetail.php?prod=5vset

I also have a ¾” endmill holder that was made by the previous owner.

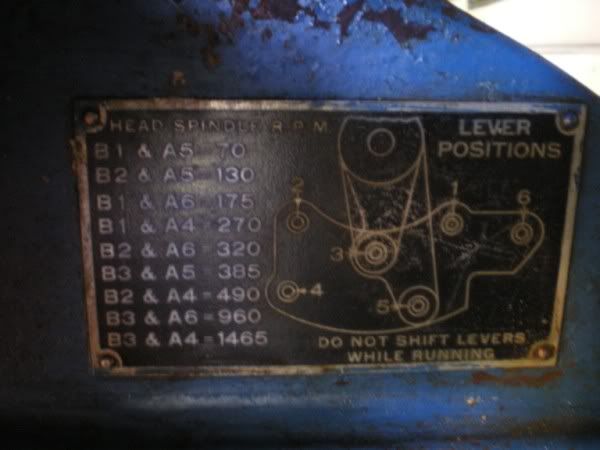

Bad news: There is a piece of the base cracked off, see pictures. The mill is still very stable though. The cracked piece does not affect function. The mill does not have a quill like a drill press. If you want to drill or plunge you have too raise the table. This is a pain but it also makes the machine more rigid and capable of heavier cuts. The seals are a little bit leaky, not too bad though. You can replace them if you are motivated. I do not have an arbor to work with the over arm support in horizontal mode. The top speed is not very high at 1465 rpm. The automatic feed for the x axis really needs an overhaul. I have not tried to use it. The parts for the auto feed all look good, complete, not broken, but messy. The auto feed gear box could use a cleaning. The sight glass for the auto feed gearbox is broken. This is easy to fix, I can show you.

The machine weighs about 2000 lbs. I can help load with my engine hoist shop crane.

Thanks,

Curt

The mill in vertical mode:

The mill in horizontal mode with the over arm support:

Cool war plate:

The cracked base:

Magnetic starter: