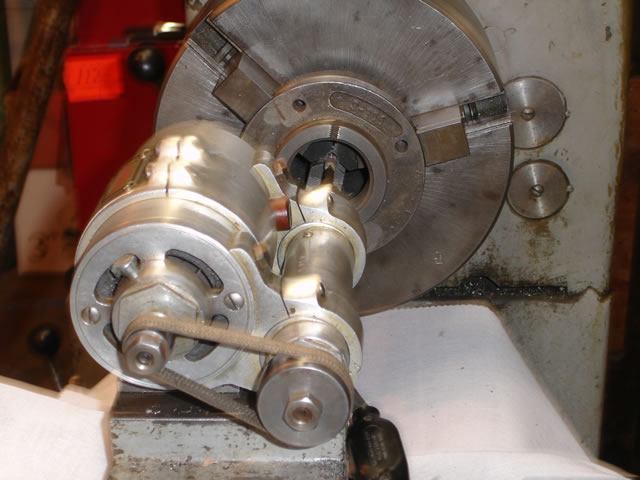

I checked the spindle before purchasing it (with the collet closer mounted) and only got about half a thousandth runout. I mounted the chuck once I got it home and found that it was out just over three thou.

I unmounted the chuck and checked at the spindle nose. As can be seen from the photo, the spindle nose is out by just over two thousandths:

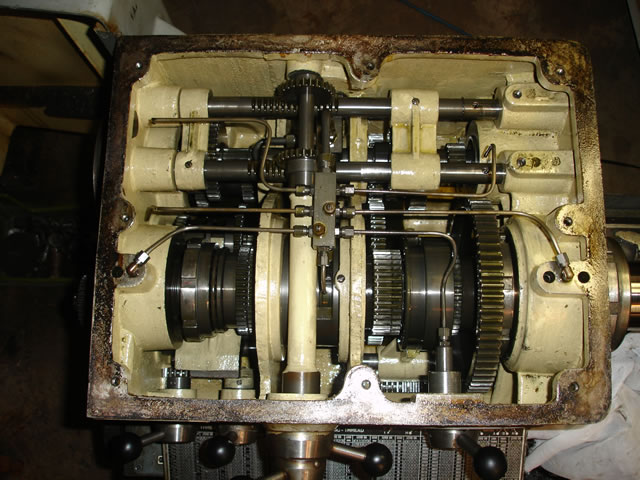

I checked the spindle for play and found nothing. Next, I attempted to check the taper fit, but the split ring prevented me from getting a good seat. I decided it was best to pull the spindle out and do the fit on the bench. I opened the gearbox and removed the bearings:

I was surprised by the condition of the bearings. This lathe was built in 1957, and the bearings still look pretty good:

Next I pulled the spindle out. I got it on the bench, removed the key from the taper, and hand fitted the backing plate to the spindle. Here's the result of the test fit:

I obviously have a problem with the spindle taper. I got the same results when I fitted the spindle to the chuck and the collet closer.

Now I have to figure out how to fix it. More to come on that.

-Arthur Fuege

Somerset, New Jersey[/img]