Voltage transformer

Moderator: crzypete

-

blackcreek

- Posts: 17

- Joined: Wed Apr 18, 2007 1:34 pm

- Location: connecticut

Voltage transformer

Hello fellow junkies.

I recently purchased an edge sander. The machine looks to be in good condition and the only problem is it requires 3ph 440v.I knew this when I bought it and perhaps it why I got it for such a good price. Anyway, in order to fire it up I need a transformer to convert my existing 3ph 208v. I have thought about anew motor or rewinding the existing one but all the controls on the machine are wired for 440v so I think that is a non starter. abit about the machine- it has 2 motors 4.5 hp for the drive and 1/2hp for the oscillation and separate controls for each as well as universal kill and an emergency stop.

I spoke with my local electric motor, guy he told me it would cost about a $1k for the proper transformer. He did all this math including square roots to figure out the size etc. All seems a bit complicated to me. Needless to say I need to find a cheaper solution. Not sure how much of his estimate was labor... there was a lot of math, and how much was the transformer. The math shows a 3.75 KVa requirement for 5 hp motor. of course transformers only come in certain sizes so he suggested a 3ph 6KVa w/ taps. My research has shown that the taps help regulate for varing inputs of voltage. As I said I have 3ph @ 208 v and the machine reqiures 440v so I would need the taps to get me from to 208v to 220v which will then be transformed to 440v. I dont know how critical all this is as the speed of the motor can vary abit without loosing any efficiency. Then there is the issue of WYE or Delta. This getting to be beyond my comprehension.

Am I, or is he, making this more complicated that it needs to be.

Any thoughts

Thanks

BlackCreek

I recently purchased an edge sander. The machine looks to be in good condition and the only problem is it requires 3ph 440v.I knew this when I bought it and perhaps it why I got it for such a good price. Anyway, in order to fire it up I need a transformer to convert my existing 3ph 208v. I have thought about anew motor or rewinding the existing one but all the controls on the machine are wired for 440v so I think that is a non starter. abit about the machine- it has 2 motors 4.5 hp for the drive and 1/2hp for the oscillation and separate controls for each as well as universal kill and an emergency stop.

I spoke with my local electric motor, guy he told me it would cost about a $1k for the proper transformer. He did all this math including square roots to figure out the size etc. All seems a bit complicated to me. Needless to say I need to find a cheaper solution. Not sure how much of his estimate was labor... there was a lot of math, and how much was the transformer. The math shows a 3.75 KVa requirement for 5 hp motor. of course transformers only come in certain sizes so he suggested a 3ph 6KVa w/ taps. My research has shown that the taps help regulate for varing inputs of voltage. As I said I have 3ph @ 208 v and the machine reqiures 440v so I would need the taps to get me from to 208v to 220v which will then be transformed to 440v. I dont know how critical all this is as the speed of the motor can vary abit without loosing any efficiency. Then there is the issue of WYE or Delta. This getting to be beyond my comprehension.

Am I, or is he, making this more complicated that it needs to be.

Any thoughts

Thanks

BlackCreek

Hello,

My experience was with a 550V Single End Tenoner, I used Fargo Electric in Buffalo, NY and my recolection was 600 was the cost and I believe your solution requires less beef, give them a try. www.fargoelectric.com

Good luck,

Brad

My experience was with a 550V Single End Tenoner, I used Fargo Electric in Buffalo, NY and my recolection was 600 was the cost and I believe your solution requires less beef, give them a try. www.fargoelectric.com

Good luck,

Brad

Hi BC, You are definitely going to want to be buying a used transformer. They are common and stocked by dealers of such.

The 208/220 thing is not a problem, generally with voltages and WW machinery, within 10% is good enough.

Also, did you check the box on the motors to see how many leads they have- if they have 9 leads it is a dual voltage motor and you simply have to swap out the coils and heaters in the mag starters. I am assuming the plates on the motors say 440 only.

Pete

The 208/220 thing is not a problem, generally with voltages and WW machinery, within 10% is good enough.

Also, did you check the box on the motors to see how many leads they have- if they have 9 leads it is a dual voltage motor and you simply have to swap out the coils and heaters in the mag starters. I am assuming the plates on the motors say 440 only.

Pete

-

mr douglas t

- Posts: 269

- Joined: Fri Dec 17, 2004 9:58 pm

- Location: Westhampton, MA

- Contact:

-

blackcreek

- Posts: 17

- Joined: Wed Apr 18, 2007 1:34 pm

- Location: connecticut

I thought I would try to post a picture to give a sense of the machine. All though is not American big iron it is industrial strength. Pete, I will take a look at how many wires are in the motor junction box in the morning If it cane be wired for 220v that would be the best case. Otherwise it is off to the surplus for a transformer. An thoughts on wye vs. delta in the wiring of the transformer? Thanks for all the advise thus far.

blackcreek

Thanks Nico for the excellent instructions on posting an image

blackcreek

Thanks Nico for the excellent instructions on posting an image

Hey BC, Not sure on the wye and delta thing other than they are two different incarnations of motors. I do not know if you need different transformers for each type of motor.

Another tidbit of info that I wanted to pass on was that it being three phase a 3Ø machine, you are going to need a 3Ø transformer- three lugs that is.

I believe there is a way to make two 1Ø transformers work, but I don;t think it is worth going down this path, just try to get the right thing the first time

Pete

Another tidbit of info that I wanted to pass on was that it being three phase a 3Ø machine, you are going to need a 3Ø transformer- three lugs that is.

I believe there is a way to make two 1Ø transformers work, but I don;t think it is worth going down this path, just try to get the right thing the first time

Pete

-

blackcreek

- Posts: 17

- Joined: Wed Apr 18, 2007 1:34 pm

- Location: connecticut

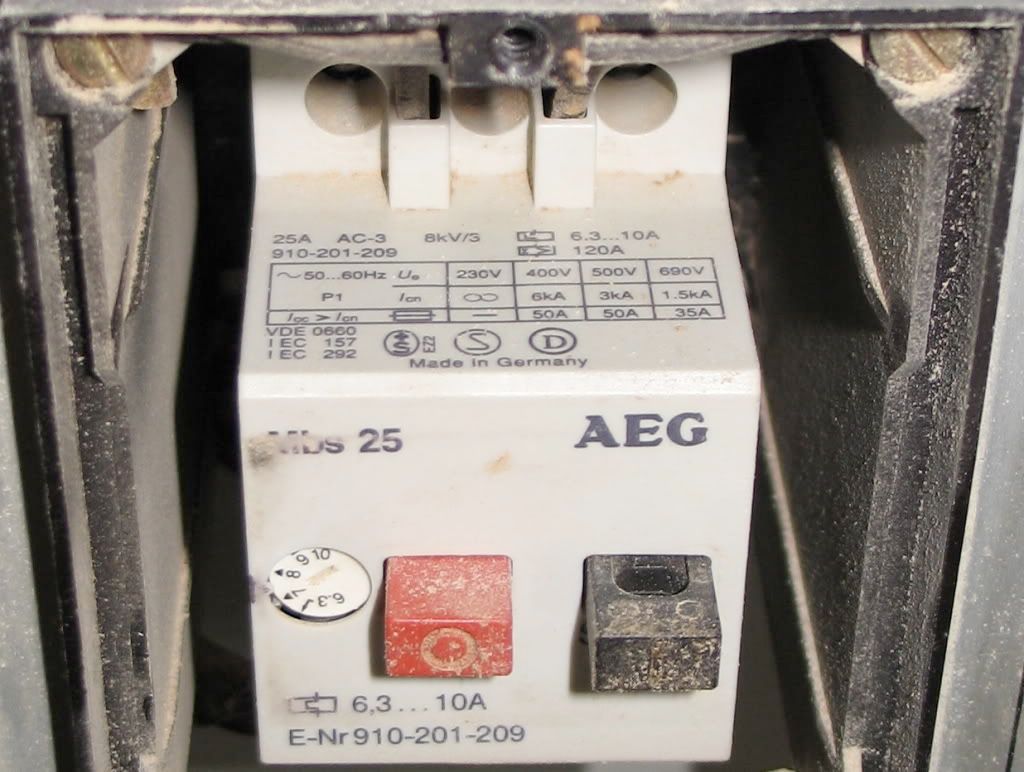

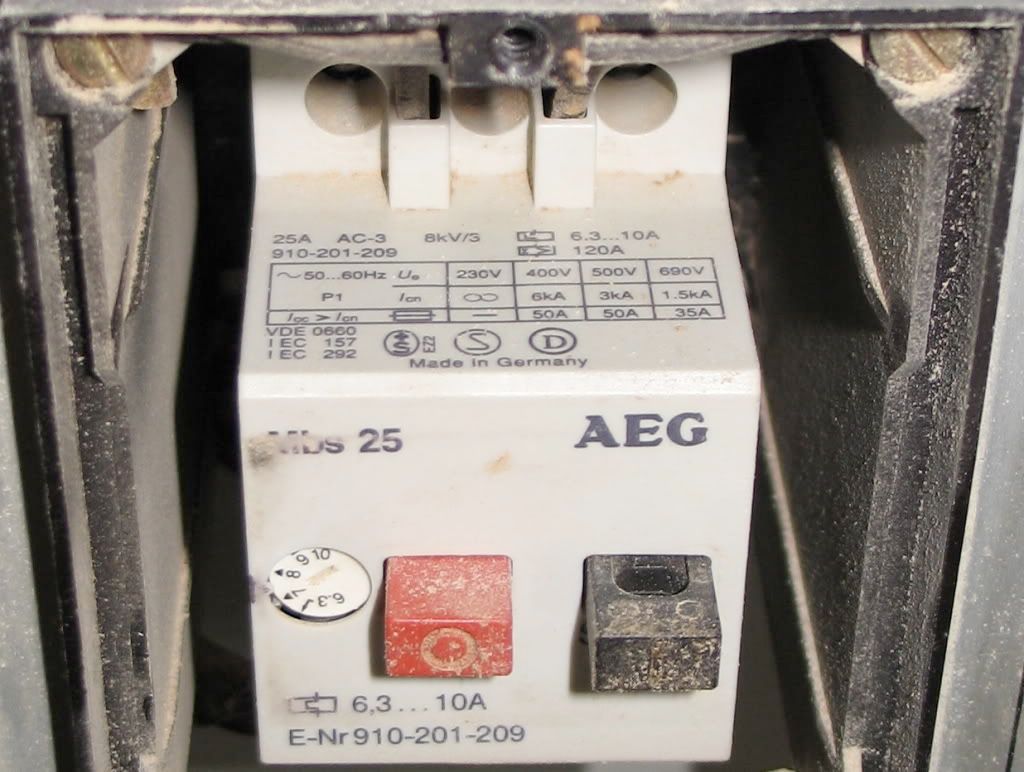

Thanks to much help and consultation from mr douglas I believe I can avoid using transformer all together. Both motors appear to be dual voltage- 440 wye/ 254 delta. This was confirmed by a lasm dealer in new milford. I assuming that when I rewire the leads in the motors they will be configured in delta which is the common method here in the US. I confirmed through the use of my multi meter that I have 208v coming into the stop start relay and no power down stream from the relay on any of the legs.

The question now is do I need to replace this relay or somehow alter its setting or wiring. I am not sure how to decipher the specs on the top of the casing. Attached is also the bottom of the casing.

So my next thought is to try and wire the machine bypassing the relay altogether to see if it works. Do I need the relay at all? It is a safety issue if the power goes out beyond that there is the emergency stop and the on/off toggles for both motors as well as the universal toggle. If so I can then try to locate a stop start relay that is appropriate.

Any insight would be helpful.

Thanks

blackcreek

The question now is do I need to replace this relay or somehow alter its setting or wiring. I am not sure how to decipher the specs on the top of the casing. Attached is also the bottom of the casing.

So my next thought is to try and wire the machine bypassing the relay altogether to see if it works. Do I need the relay at all? It is a safety issue if the power goes out beyond that there is the emergency stop and the on/off toggles for both motors as well as the universal toggle. If so I can then try to locate a stop start relay that is appropriate.

Any insight would be helpful.

Thanks

blackcreek

Good news about the motors. I googled the relay and found a spec sheet of some sort that may help you or some of the more electrically inclined people on this board.

http://www.calcentron.com/PDF_Documents ... _mbs25.pdf

The second page describes your exact starter. As I read it it is designed for multiple situations without needing to replace heaters (hence the adjustable dial). It remains unclear to me if you need to do anything more than rewire the motors?

I am sure that nothing more needs to be purchased to get this machine up and running.

EDIT- after reading your post again I just wanted to add that the starter is essential and the other switches are not designed for full current. if you bypass the relay/starter you should bypass everything. The motor should go straight to plug for testing purposes.

http://www.calcentron.com/PDF_Documents ... _mbs25.pdf

The second page describes your exact starter. As I read it it is designed for multiple situations without needing to replace heaters (hence the adjustable dial). It remains unclear to me if you need to do anything more than rewire the motors?

I am sure that nothing more needs to be purchased to get this machine up and running.

EDIT- after reading your post again I just wanted to add that the starter is essential and the other switches are not designed for full current. if you bypass the relay/starter you should bypass everything. The motor should go straight to plug for testing purposes.

you have two mtrs, 4.5 and .5 total 5 hp, at 200V your starter is rated at 2hp at 200V and 230V 3hp. first switch the Mtr. leads to low voltage, if mtrs are rated 220 -440 lead configuration should be outlined on cover plate on junction at mtr.

then give it a college try, heating will occur, how much? the heaters in starter are designed to take care of overlaod if it occurs, you can also monitor the amps you are drawing with amp probe, my exp. with euro mtrs is they are about 50% of nameplate value, same with starter? no sure, you may get lucky.

if you cannot prevent starter trip with heater sensitivity adj. you will have to replace starter

then give it a college try, heating will occur, how much? the heaters in starter are designed to take care of overlaod if it occurs, you can also monitor the amps you are drawing with amp probe, my exp. with euro mtrs is they are about 50% of nameplate value, same with starter? no sure, you may get lucky.

if you cannot prevent starter trip with heater sensitivity adj. you will have to replace starter

Hi Tom,

You definitely cannot bypas the "relays"- they are magnetic switches that provide thermal protection for your motors. The buttons that control the ma switches would not be rated to handle the voltage for the motors and are most likely not wireable in a way which will function

you need to check the top part of the switch- it has a thing called a coil which is most likely wired 440. on older switches you needed to swap out the coil to obtain different voltages. This being a modern jobby, you will probably be able to swap a couple of wires and have success.

Next you need to adjust the thermal protection at the bottom of the switch to adjust for the increased amps of the new motor configuration.

You should then press the reset button(s) on the switch(es), these often get tripped in transit and would cause the switch to act dead.

I am assuming you have been into the motors and rewired them 220.

Good luck.

Pete

You definitely cannot bypas the "relays"- they are magnetic switches that provide thermal protection for your motors. The buttons that control the ma switches would not be rated to handle the voltage for the motors and are most likely not wireable in a way which will function

you need to check the top part of the switch- it has a thing called a coil which is most likely wired 440. on older switches you needed to swap out the coil to obtain different voltages. This being a modern jobby, you will probably be able to swap a couple of wires and have success.

Next you need to adjust the thermal protection at the bottom of the switch to adjust for the increased amps of the new motor configuration.

You should then press the reset button(s) on the switch(es), these often get tripped in transit and would cause the switch to act dead.

I am assuming you have been into the motors and rewired them 220.

Good luck.

Pete

-

blackcreek

- Posts: 17

- Joined: Wed Apr 18, 2007 1:34 pm

- Location: connecticut

As it turns out I rewired the motors for 254v delta. and gave it the college try. Nothing. I then took apart the starter. Through Nico's link I spoke with supplier that referred me to AEG tech support. Inside the starter there is a low voltage trip activated by the emergency stop button. This trip coil is rated for 440v Tech support said to disconnect and or remove from starter. I thought I was golden- tried both- Nothing. Growing frustrated. checked continuity in starter with contacts engaged- no continuity. Must be a bad starter or I am missing something. Pete I see no resets on any of the switches. Anyway I have a pile of stuff that is going to be a lot easier to sand with the machine than without so I wire the drive motor directly to plug. It fires right up and three hours work with a dynabrade is done in 25 minutes. 10 minutes on ebay finds me a new AEG starter rated with 10-16 amp which should handle it at 208v for $50. Hopefully that will do it as i am stretching the limits of my typing ability. If not I will be back for more analysis.

Thanks to all for your help.

blackcreek

Thanks to all for your help.

blackcreek

Tom, a few more thoughts before you go through the trouble of swapping the switch.

Perhaps the off button on the contact block is the reset- press it and then try.

Perhaps the mushroom button is a locking one that needs to be twisted to release and allow it to start.

Such a modern starter, I would be surprised if it were DOA.

Also, welcome to the world of edgesanders- I believe them to be perhaps the biggest timesaver of a machine in the shop- I run mine with a 150 belt and barely need to touch it afterwards.

Pete

Perhaps the off button on the contact block is the reset- press it and then try.

Perhaps the mushroom button is a locking one that needs to be twisted to release and allow it to start.

Such a modern starter, I would be surprised if it were DOA.

Also, welcome to the world of edgesanders- I believe them to be perhaps the biggest timesaver of a machine in the shop- I run mine with a 150 belt and barely need to touch it afterwards.

Pete

-

blackcreek

- Posts: 17

- Joined: Wed Apr 18, 2007 1:34 pm

- Location: connecticut

So I have finally gotten around to working on the sander again. I recieved and installed a new AEG starter rated w/ the proper amperage. Plug it in and it works... sort of. Turn the switch for the drive motor and the belt goes round and round. Even in the right direction on the first try. Turn the toggle switch for the up and down motion and nothing... life should never be easy. So I get the multi meter out I have 208 coming into all of the legs of the switch... with the switch engaged (on) I have 208 in one leg and about 104 in the other two. What's up with that. Bad switch? (It is the same exact switch as the drive motor switch which has 208 in and out on all legs). So my question is do I need all these separate switches anyway. Is there any value to having the up and down isolated from the drive or should I lump both movements on to one switch.

Any thoughts

Thanks

Tom

Any thoughts

Thanks

Tom

Tom, One reason for a separate switch is to thermally protect each motor. If you simply turned the heater up to account for both motors, you would need both motors to get hot enough to trip the overload, This would not protect against one going bad or jamming while the other was riding free and easy.

Double check you wiring diagram and compare everything to the switch that is working. Hopefully it is something simple.

Pete

Double check you wiring diagram and compare everything to the switch that is working. Hopefully it is something simple.

Pete

-

blackcreek

- Posts: 17

- Joined: Wed Apr 18, 2007 1:34 pm

- Location: connecticut

Thought I should rap up this thread. As it turns out the switch was full of dust and not making a good connection when engaged. A good blow with compressed air solved the problem. I should have thought of that sooner. Never did figure out the voltage issues but decide that since it seems to be working properly I would let that sleeping dog lie.

The purchase has made me rethink my shop layout and the several machines moved around before the sander found its more or less permanent home. So far in limited use I have found that this machine has the potential to save me a lot of time. It has already been making me some money so no regrets even with the minor hassles. I am still curious about the issue that swparish brought up but I will save that for his thread.

Much thanks is due to the many junkies who have responded to the posts and helped me reason out the problem. Mr Douglas deserves special note for nudging me to see beyond a transformer to begin with and to start poking a round with my voltage meter. Unfortunately, he talked himself out of a sale of a transformer while saving me a some good money.

Best,

Tom

The purchase has made me rethink my shop layout and the several machines moved around before the sander found its more or less permanent home. So far in limited use I have found that this machine has the potential to save me a lot of time. It has already been making me some money so no regrets even with the minor hassles. I am still curious about the issue that swparish brought up but I will save that for his thread.

Much thanks is due to the many junkies who have responded to the posts and helped me reason out the problem. Mr Douglas deserves special note for nudging me to see beyond a transformer to begin with and to start poking a round with my voltage meter. Unfortunately, he talked himself out of a sale of a transformer while saving me a some good money.

Best,

Tom