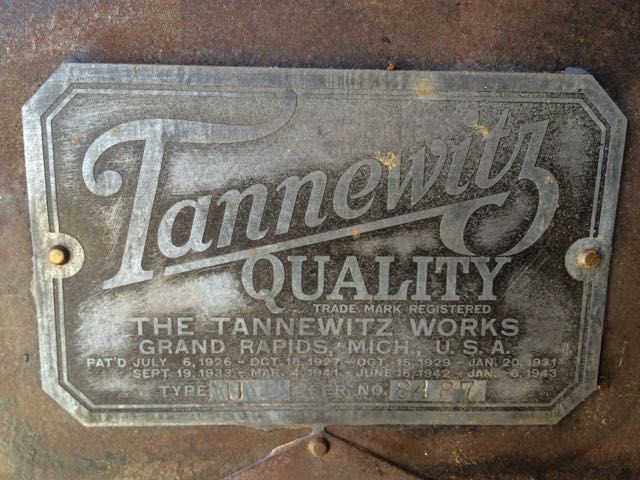

Tannewitz Type U Restoration

Moderator: nektai

Tannewitz Type U Restoration

I'm in over my head but drawing inspiration from Pete and Stephen. This saw appeared on CL over 4 months ago. it disappeared and about 2 months ago, on a whim, I texted the number I had saved. He still had the saw and was asking $250. It has "issues". The height adjuster was rusted, busted, and braised together. The trunnion was not bolted down (loose on the cabinet), rusted, busted, and braised together. When power was applied, the motor just hummed- it was single phasing. The top has only slight surface rust but has a 1/16" crown- I think from the motor being forced against it from below. I got it for $100. I think I can solve everything but the motor without putting another mortgage on the house. I got one estimate for a rewind for $1000. That's not going to happen. I could really use some advice. I'd like to have this replace my Craftsman TS rather than just part it out on ebay.

Terry

rack and pinion fence

I was glad to get this. Even if I can't get the saw functioning, this should be worth the price of admission. I didn't get the tapered pins. I will have to find replacements.

Terry

pulling the guts

this thing is a beast. It brought my little toyota down to the axle. I rented an engine hoist to get it out of the truck and now I'm using a cable puller to pull out the trunnion and motor.

Terry

height adjustment

This was rusted solid. I've finished the rust removal and need to order a replacement for the thrust bearing. It's completely functional now and looks pretty good. it's nice to have one victory behind me. The weld job is ugly but it works.

Terry

That saw looks rough, but it is amazing how you can rescue these things. I would certainly pull apart that motor and try to visually inspect it before assuming it needs rewinding. Sometimes simple things are the culprit. Although the new nuts on the end of the housing make it seem that someone may have already been inside. Also, always check the wiring diagram t make sure it is wired correctly. Especially if it is a 220-440 motor.

$1000 is definitely high for a rewind, shop around and see if you can beat that- you may find substantial savings.

Pete

$1000 is definitely high for a rewind, shop around and see if you can beat that- you may find substantial savings.

Pete

Tannewitz

Pete, Thanks for the advice. I'll pull the motor apart, provided I can get past the infamous retaining nut. Will the wiring diagram be on the inside of the fan cover? I haven't been able to find any documentation on the motor.

Thanks

Terry

Thanks

Terry

Terry

motor leads

Terry

motor toast

the single phasing mystery is solved. Completely toasted. I think this saw is headed for scrap.

this is the good end.

[/img]

[/img]

this is the other...

[/img]

[/img]

[/img]

[/img]

Parts?

this is the good end.

[/img]

[/img]this is the other...

[/img]

[/img] [/img]

[/img]Parts?

Terry

Yup, That's pretty toast. A couple of options. You can try to find a cheaper shop to rewind. Look for a replacement motor- I would post over at Owwm. Or part it out and scrap the rest.

I'm not sure where you are in the country, but saws like this do come up pretty frequently, so not the end of the world.

The fence should easily reap back your investment. If you got miter gages they are pretty good too. Definitely save/sell the big hand wheels too. Also, the fence extension piece on the table and the stub arbor. I'd post on OWWM if you are parting it out.

Pete

I'm not sure where you are in the country, but saws like this do come up pretty frequently, so not the end of the world.

The fence should easily reap back your investment. If you got miter gages they are pretty good too. Definitely save/sell the big hand wheels too. Also, the fence extension piece on the table and the stub arbor. I'd post on OWWM if you are parting it out.

Pete

I'm in San Diego. We don't see big iron on CL very often. There's a Northfield #4 that's been on for a couple of months ($3,500) and not much else over the past year.

I pulled the copper from the stator and cleaned it up a bit. I'll get a couple of more quotes for rewinding before I make the final decision. It came with one miter gage that does have all the parts. So far, I've been unsuccessful in removing the stub arbor. I'll try putting a torch on it for a couple of heating/cooling cycles.

Terry

I pulled the copper from the stator and cleaned it up a bit. I'll get a couple of more quotes for rewinding before I make the final decision. It came with one miter gage that does have all the parts. So far, I've been unsuccessful in removing the stub arbor. I'll try putting a torch on it for a couple of heating/cooling cycles.

Terry

Terry

Best quote I could get on the motor was $800. I did find a couple of replacements for a lot less but they looked pretty sketchy and combined with the other issues, I sold for scrap. For the life of me I couldn't get the stub arbor off. So, it went with the scrap. The table extension had most of the pin placements welded over and it had been busted and repaired once as well. Couldn't see that until I had it apart. It was deeply gouged on the surface (3/8"). It went scrap as well. I saved the Miter (great shape), Angle adjustment mechanism (fair shape), Starter( original on/off and mag reset, surface rust but working), two hand wheels, Elevation mechanism (broken, welded, works). R&P fence (great shape, some witness marks, no pins), arbor flange nut. I'm going to keep the elevation mechanism for a 36" drum sander I'm building but the rest is going to be parted out. I'll post on OWWM as you suggested.

Thanks for the advice. I wish it went a different direction though. I'll have to wait a couple more years to retire before I can really indulge in the Old Arn.

Thanks for the advice. I wish it went a different direction though. I'll have to wait a couple more years to retire before I can really indulge in the Old Arn.

Terry

[/img]

[/img]