I recently got an email from crzypete stating HERE IT IS!!!! and a hyperlink underneath it. I clicked on it and there it was a Walker Turner 16” W/M band saw. It was rough but the price was right. So I emailed the person as there was no phone number to call and waited for a response. I assumed it was gone due to it had been posted for a couple of days and I was just getting to it then.

I received and email back from Dave (Ironically the last 4 of 6 CL transactions I have had have been with people that share my name). Dave said he had two other people interested in it but if I wanted to come take a look at it I could come up on sunday. So I packed all of my cribbing and tie-downs and made sure I was ready for anything for when I went to get it.

Dave is located north of Lake Placid so it was a beautiful day for a drive into the Adirondack Park. I filled up the truck with gas and got on the move. When I found his address I had about a 1 mile drive down a rough dirt road and everything about it screamed in my head that I was going to be butchered and buried in different places all over this guys backyard. With great comfort and surprise though as I rounded the last corner of the drive way I saw a 7 foot tall vertical stack of rocks precariously placed on top of one another. I knew only good things could come from this place.

I pulled up to the first of 3 of Dave's Barns. He came out of the house and shook my hand and we went about business. We walked out to his shop and took a look at the saw. I gave it a good through check and even fired it up. Everything was in good working order considering the state it was in and I told him I'd take it. So I got him talking as we were loading up and found out that he moved up that way in the early 70's and was training for the 76 and 80 Olympics for the luge and the bobsled. He had a terrible accident competing and spent 9 month in a hospital bed in Germany with 57 steel rods in his foot while it healed. Fortunately he is able to walk because of all of the time he took to let things heal right.

After that he started building the bobsleds and luges for the US Olympic team and worked as their manager. He also let me know that I was the last person to contact him but he checked out my website liked the work and thought the saw if I wanted it would go to a good home. So he called me first. First time my art practice has ever gotten me preferential treatment. Dave is now retired and restores fire towers for private investors and designs and build gyrocopters. Cool dude.

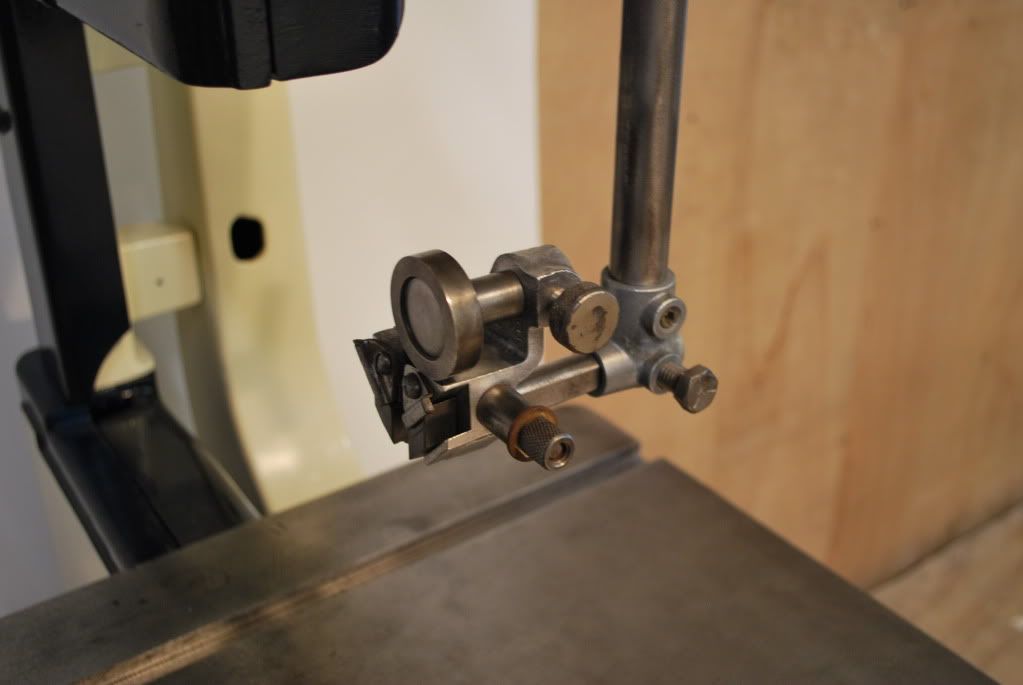

So enough rambling. Here are the pics.

Nice day for a drive north

Past this shop on the way to Dave's house. I knew I was headed in the right direction.

loaded up on the road

nothing like a new toy thats going to take you weeks to actually get to use to make you happy!

stopped for lunch in Keene. Good food but the best part was watching people walk by it trying to figure out what it is.

home...

in the shop next to the delta 14" makes it look like a baby.

painting the trim today on the drill press, sourced a motor and hopefully will have it all back together and wired this week....

then I have a sander to work on...