The best machines

Moderator: crzypete

The best machines

I spent the day sanding, so my brain spent too much time wandering. I started thinking about which manufacturers made the best of which machines. Thought it would make a good topic of discussion.

so who made the best bandsaw? I would think different manufacturers could get get credit for different sizes.....

who made the best tablesaw.....etc etc etc.

Pete

so who made the best bandsaw? I would think different manufacturers could get get credit for different sizes.....

who made the best tablesaw.....etc etc etc.

Pete

best machines

the early martins such as the T-17 are very sought after, this vintage is prior to the "beam" type martins of present, in my opinion the martin T-17 is one of the best table saws

next...

later

next...

later

-

soubre

-

soubre

For joiners I looked at northfield and oliver , either you buy in that the wedge bed will always always always be true (and if not how the hell do you get that thing up on a blachard grinder) or you get a 166 that you can fiddle with the 4 little ramps on the corners. Mine is a 16" 1930's vintage that i have moved twice and been able to dial it right back in with a long straightedge and dial indicater.Im sure the fact that most people (that went to rit) either have one or want one has absolutely nothing to do with the fact that we were all deeply moved by the sound of the 18" oliver powering up.

-

mr douglas t

- Posts: 269

- Joined: Fri Dec 17, 2004 9:58 pm

- Location: Westhampton, MA

- Contact:

oliver powering up

As Mr Soubre has pointed out, RIT alum, seem to have a special foundness for the 166 Oliver Jointer. After graduation my two desires for machinery were an Oliver 16 jointer and a Bridgeport Mill. I have met my goals and even exceeded them by 4 inches.

I think the Oliver 166's have a number of advantages, aside from the fabulous adjustment as pointed out by soubre, they seem to be very compact in width.

It seems a lot of the three legged beast out there have extra inches added to the table for no reason- they become massive for no reason.

Also seems like oliver was able to make the tables longer because of the longer supporting base.

they seem to be popular even outside of the RIT circle.

pete

It seems a lot of the three legged beast out there have extra inches added to the table for no reason- they become massive for no reason.

Also seems like oliver was able to make the tables longer because of the longer supporting base.

they seem to be popular even outside of the RIT circle.

pete

-

soubre

Although some of the olivers had a draft adjustment that would tilt the bed along its long axis( nifty for foundrymen but not much use to furniture makers) Ive only seen a sprung joint adjustment on wedgebed style joiners, that would drop the back of the outfeed bed ever so slightly to give a barely hollowed jointed edge perfect for table tops, etc. Thats the only thing a northfield's got on an oliver.

a bit bit belated, but i am just now reading the post 20 days after my post suggesting the Martin T17 as a front runner for best TS, in his hesitation being and Oliver fan, i think they (Oliver) got confused between a gvmt contract for boat anchors when they started producing TS's anyway, anymore votes out there for the top TS, we actually should have sub catagories for TS, Variety, Rip, Beam sliding and Table sliding

my votes:

Variety- 50's unisaw

Rip- Oliver

Beam slider- Altendorf F45 10'- short stroke Martin T17

Table sliding- Hammond G-100

my votes:

Variety- 50's unisaw

Rip- Oliver

Beam slider- Altendorf F45 10'- short stroke Martin T17

Table sliding- Hammond G-100

-

klavelle72

- Posts: 18

- Joined: Fri Mar 10, 2006 11:36 pm

- Location: Belleville, IL

I think we need to consider the era of machinery a bit here as well.

Bandsaws: J. A. Fay & Co., later J. A. Fay & Egan Co., was the real innovator here. By 1874 they had many refinements including a blade brake which are still used in one form or another to this day. In later years they may have been surpassed by Tannewitz or Yates.

Drum sanders: Berlin, later changed name to Yates, had monster drum sanders very early. They had all sorts of refinements and weighed up to 12,000lbs. Later there was Solem and Beach.

Stroke sander: Fay & Egan, Wysong & Miles. Both big and powerful and simple in design.

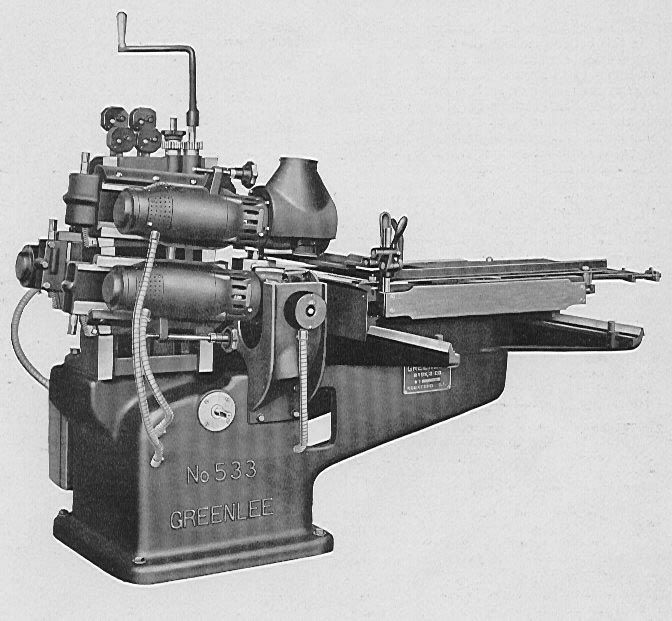

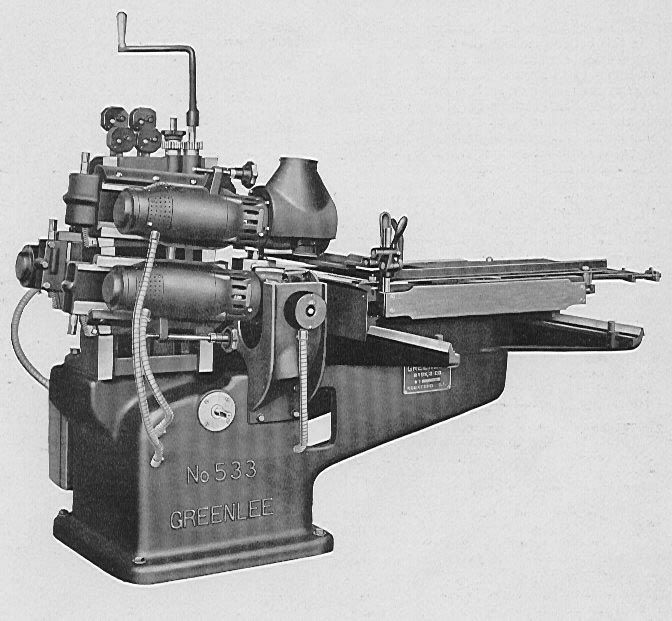

Mortisers: Greenlee was the innovator in hollow chisel mortise machines.

Lathes: Oliver is among the biggest and best I've seen.

Tenoners: Levi Houston's 1877 patent is still seen alot as far as belt driven ones. Later, there were many, many good makers of direct drive machines. The most common, though smallest, is Millbury.

Ripsaws: Most guys rave about Mattison and Deihl.

Planers: I've heard great things about S. A. Woods.

Bandsaws: J. A. Fay & Co., later J. A. Fay & Egan Co., was the real innovator here. By 1874 they had many refinements including a blade brake which are still used in one form or another to this day. In later years they may have been surpassed by Tannewitz or Yates.

Drum sanders: Berlin, later changed name to Yates, had monster drum sanders very early. They had all sorts of refinements and weighed up to 12,000lbs. Later there was Solem and Beach.

Stroke sander: Fay & Egan, Wysong & Miles. Both big and powerful and simple in design.

Mortisers: Greenlee was the innovator in hollow chisel mortise machines.

Lathes: Oliver is among the biggest and best I've seen.

Tenoners: Levi Houston's 1877 patent is still seen alot as far as belt driven ones. Later, there were many, many good makers of direct drive machines. The most common, though smallest, is Millbury.

Ripsaws: Most guys rave about Mattison and Deihl.

Planers: I've heard great things about S. A. Woods.

-

mystry_tour

- Posts: 357

- Joined: Mon Mar 13, 2006 9:33 pm

- Location: Greenville Tenn

Millbury's came in different configurations, all that I have seen came with cope spindles from the factory but that does not mean that someone did not chuck them. The early ones had upper and lower stub copes and the later machines like the one I own came with a long upper cope spindle. While a great small machine there are certain limitations with the Millbury so be sure of what you want to do with it.

two reasons to own a millbury, one if you live in "Millbury" Mass. and would like a pc. of local history or if you had a touring woodworking shop in the back of truck and need a compact benchtop type SET.

i owned a millbury for many years and it served me well, actually vibrated so much it would follow me around the shop, good company. a 5 station machine with primitive cope disc's that made wonderful paper weight's being finely machined in bronze, never really coped with it (no pun intended) mainly used it for cabinet door tenons (have allways been partial to square edged doors for shaker stlye or molded panel type)

the millbury is essentialy a powermatic 2A or vice versa, almost think the millbury came first. endless belt powers the top & bot, and cutoff saw, my configuration used a two sided mtr with a fancy horizontal to vert twist in the cope drive belt as i remember.

you really will be far better served with Greenlee 534, Fay and Egan 505, Oliver, L Power, Wadkin DMD Type machine, believe depending on the deal it is worth the extra 2 - 4 thousand bucks, still see millburys and 2A's going for near 2 grand? why i don't know, actually sold mine to a guy just outside of... Millbury Mass.

i owned a millbury for many years and it served me well, actually vibrated so much it would follow me around the shop, good company. a 5 station machine with primitive cope disc's that made wonderful paper weight's being finely machined in bronze, never really coped with it (no pun intended) mainly used it for cabinet door tenons (have allways been partial to square edged doors for shaker stlye or molded panel type)

the millbury is essentialy a powermatic 2A or vice versa, almost think the millbury came first. endless belt powers the top & bot, and cutoff saw, my configuration used a two sided mtr with a fancy horizontal to vert twist in the cope drive belt as i remember.

you really will be far better served with Greenlee 534, Fay and Egan 505, Oliver, L Power, Wadkin DMD Type machine, believe depending on the deal it is worth the extra 2 - 4 thousand bucks, still see millburys and 2A's going for near 2 grand? why i don't know, actually sold mine to a guy just outside of... Millbury Mass.

exfactory auction of Oliver 125D tilt table oh baby oh!

nice rig,

http://www.exfactory.com/Auctiondetail. ... pp=Auction

nice rig,

http://www.exfactory.com/Auctiondetail. ... pp=Auction

now that we are on the SET topic, my vote for best machine comes down to 2 machines, still on the fence

OLIVER 125D

GREENLEE 533

OLIVER 125D

GREENLEE 533

Last edited by dadude on Fri Apr 14, 2006 8:45 am, edited 1 time in total.

-

mystry_tour

- Posts: 357

- Joined: Mon Mar 13, 2006 9:33 pm

- Location: Greenville Tenn

for the time being all I want to do is square face frames and square cabniet doors....nothing fancy but square. They are popular around this area. face frames for shaker type vanitys. If I need to do something fancyer later I will shell out the cash but I really have no need at the moment

I fought to keep the Gov. in power......they keep screwing around I'll fight to get rid of them.

seems like we've turned the post into a forum about tenoners, in respect to the millbury or powermatic 2A, try and find one at a reasonable cost keeping in mind it is only going to be as good as the tenoning heads, the stock heads have a two curved knives and inserted shoulder cutters, the heads are very paticular in sharpening and setup, if you luck out and locate a machine with updated heads (500-750 $$) bingo, but unlikely. also the cutoff saws are on a movable collar, make sure the collar is with the machine, they are pricey after the fact. i did not approve of the holdown feature on my millbury so i built a simple air hold down that worked well and was easy enough to fabricate, goodluck with finding a machine, if i see one i will pass on info.

Without any doubt the Millbury has it's weak points but on the up side it's very small for a SET. The tenon heads just downright look scary but I have tried different heads including insert heads and nothing cuts like a HSS Millbury head when sharp. Go figure. Keeping them sharp is another story and if it was not for the fact that we grind all of our tooling (HSS) and therefore have a profile grinder it would be a big factor. I know of 3 people looking for the saw collar if anyone has one.